Within a sugar mill, one of your most important goals should be to maximize energy efficiency. This not only can significantly reduce your operating expenses but also reduce product loss, improve equipment lifespan, increase output, and reduce risks. This can also support your mission if you’re striving for a more environmentally sustainable factory to reduce your carbon footprint. Read more to discover what areas of your sugar mill could be improved to see the most impact.

Preparation

You can optimize even the earliest stages of sugar milling before the sugar even begins to be processed by ensuring that your transport system between farm and mill is efficient. Ensuring that there is very little idle time between harvest and pickup ensures that you’re dealing with the highest quality and freshest cane, ensuring you have a proper level of brix. This will ultimately make your entire operation more efficient because you’re starting the process with optimal raw material that is least likely to create additional needs for cleaning and sterilization (reducing water, energy, and human resources use), as well as reducing the chance for poor output at the end.

Juice Treatment

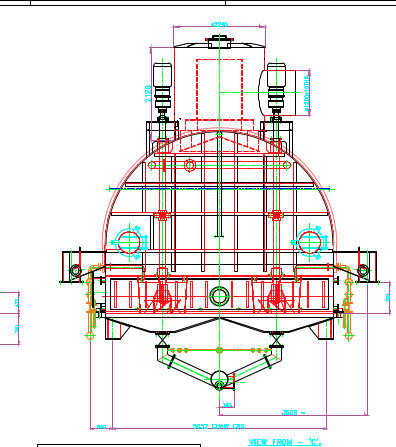

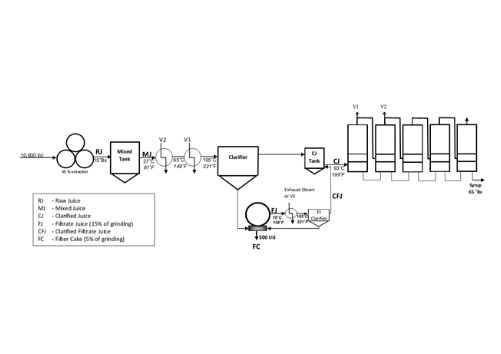

During the juice extraction process, there are a few key points to improve to boost your energy savings. When working with our engineering team, we ensure that there is always a stable juice flow since an inconsistency in juice flow affects the rate of heating and liming efficiency. Another common problem we diagnose in sugar mills is that there is not a quick enough sludge evacuation. This can cause short-circuiting and put added strain on your energy use if not handled properly. We often use the Crompion Clarifier to improve the overall quality of the juice and increase your factory’s yield and cut unnecessary losses.

Evaporation and Crystallization

One of the biggest optimizations you can make to improve energy efficiency in the evaporation process of your mill is to reduce and reuse waste heat. We make it a point to install heat exchangers that will significantly reduce your energy use and waste by using the heat from the hot process streams to heat other parts of the process where heat is also needed, therefore reducing the heat needed.

CTA: If you’re ready to make improvements to your sugar mill that reduces your energy usage, get in touch with our expert engineering team to help you maximize efficiency through the Mass & Energy balance (M&E) and Factory Report diagnoses, and from there, we will collaborate on a plan to replace any equipment, improve factory layout, and correct any lingering issues that is causing shortfalls in your sugar production.