Introduction:

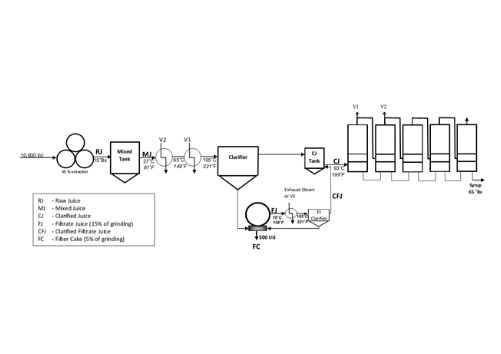

In the complex world of sugar processing, understanding the impact of various compounds is crucial for maintaining efficiency and quality. Two such compounds, dextran and starch, play significant roles in the sugar process. In this article, we will explore the origins of dextran and starch, their effects on sugar process performance, and the control measures employed to mitigate their adverse effects. Additionally, we will delve into the application of enzymes, such as dextranase and amylase, in managing dextran and starch-related challenges.

What is Dextran?

Dextran belongs to a family of polysaccharides that are infrequently found in healthy sugarcane plants. It is a gummy substance resulting from the polymerization of dextrose, a product of sucrose degradation. Certain lactic-acid bacteria, like Leuconostoc mesenteroides, produce the dextran sucrase enzyme, which facilitates this polymerization process. Dextran consists of high molecular weight chains linked by α-1,6 glycosidic linkages between glucose molecules, with branches occurring at α-(1-3) or α-(1-4) or α-(1-2) positions. The formation of dextran typically occurs after the harvesting of sugarcane.

What is Starch?

Starch is a natural polysaccharide present in sugarcane. It is a mixture of linear (amylose) and branched (amylopectin) components in a ratio of 20:80. Amylose is a polymer of glucose units linked by α–1,4 linkages, while amylopectin is a highly branched polymer with branches occurring at α–1,6 linkages. Starch concentration in sugarcane varies depending on factors such as cane variety and growth conditions.

Effects of Dextran on Sugar Process:

Elevated dextran content in sugarcane juice can lead to various challenges in the sugar process. Dextrans are highly dextro rotatory, which affects sucrose determination by polarization. Moreover, the conversion of sucrose to dextran incurs a yield loss of about 25%, resulting in unnecessary sugar loss. The presence of dextran increases viscosity, hampers heat transfer, prolongs boiling time, and affects crystal elongation during massecuite boiling. It also influences the quality of refined sugar and acid beverage floc formation, while making sugar drying and packaging more challenging.

Effects of Starch on Sugar Process:

Starch content in sugarcane juice can cause operational issues during the sugar process. Higher viscosity and starch content adversely affect setting and filtration rates, reduce the capacity of the plant, increase pan boiling time, and necessitate larger quantities of wash water during centrifugation. Starch also hampers clarification, lowers sugar quality, and causes turbidity in sugar solutions, limiting its use in acid or alcoholic beverages.

Control Measures for Dextran and Starch:

To mitigate the adverse effects of dextran and starch, several control measures can be implemented. Harvesting of immature or over-mature cane should be avoided, and proper cane transportation management should be ensured to minimize the time gap between harvesting and crushing. Maintaining cleanliness in the cane yard and applying biocides at mills can also help reduce dextran and starch contamination. Additionally, the application of enzymes, such as dextranase and amylase, has proven effective in controlling dextran and starch-related challenges.

Dextranase and Amylase Enzymes:

Dextranase is an enzyme that hydrolyzes dextran into reducing sugars. It is produced by microbial strains and functions optimally at temperatures between 50 to 60°C and a pH of 5.2. Dextranase activity is measured in International Units (IU), representing the amount of enzyme that liberates 1 micro mol glucose equivalents per minute. Amylase, on the other hand, hydrolyzes starch molecules into smaller glucose polymers. Both enzymes can be utilized to manage dextran and starch-related issues in the sugar process.

Conclusion:

Dextran and starch play significant roles in the sugar process, affecting various stages from juice clarification to crystallization and refinement. Understanding the origins and effects of dextran and starch is crucial for maintaining process efficiency and sugar quality. By implementing control measures and utilizing enzymes like dextranase and amylase, sugar processors can effectively manage dextran and starch-related challenges, leading to improved productivity and higher-quality sugar products.